By law, owners of businesses or property are required to take reasonable steps to ensure the safety of the general public. The South African Compensation commissioner reported a total of 200 000 to 220 000 claims per year in the workforce due to slips, trips and falls, many of which have resulted in either loss of life, loss of quality of life and have incurred suffering.

Have you considered how you can change this statistic with mindful specifying?

Are trips and slips a real problem?

YES! Slips, trips, and falls are the highest risk factor for people in any building, regardless of its purpose. Slips, trips, and falls can lead to injury, lost working hours, litigation, and even death.

Click here for our infographic which summarises information on the prevalence and cost of trips, slips and falls in the USA, UK, and South Africa.

What factors cause trips and slips?

Slips, trips, and falls are divided into two categories:

- Same-level falls: e.g. slipping on a wet or oily surface.

- Falls from a higher level or uneven surface: eg. falling up or down stairs.

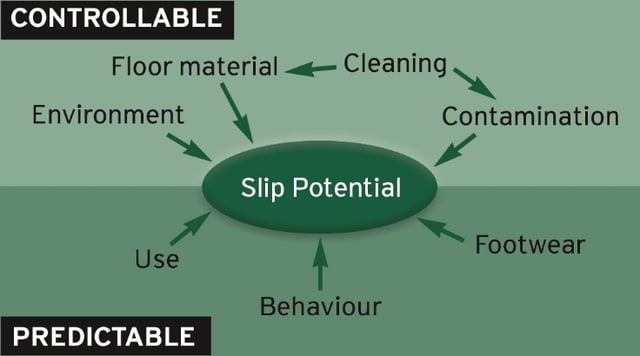

The Health and Safety Executive (HSE) in the UK has designed a very useful ‘Slip Potential Model' which helps to analyse the importance of potential factors contributing to a slip.

Factors are classified as controllable, such as flooring-type, cleaning, and contamination; or as predictable, such as expected-use patterns and the users’ likely behaviour and footwear.

How can we prevent trips and slips?

Understanding the types of falls that occur, and use of the HSE Slip Potential Model allows identification of areas in a building that are likely to create a high-risk for slips, trips, and falls.

Areas in a building commonly classified as high-risk include:

- Food-preparation areas, including commercial kitchens, bars, restaurants, hotels, canteens, and home economics kitchens in schools.

- Bathrooms, showers, and changing-rooms.

- Scientific, medical, or school laboratories.

- General-purpose areas which could become slippery, including entrances and ramps.

- Transport vehicles, including buses and trains.

- Stairs

- Any continuously wet area, such as indoor swimming pools and hot-tub areas.

Once this analysis is complete and high-risk areas are identified, it becomes the architect’s duty of care to source and suggest the correct solutions for prevention of slips, trips, and falls in these areas. As seen within this article highlighting the flooring used at the Chris Hani Baragwanath Academic Hospital.

Four factors require consideration when selecting potential solutions to prevent slips, trips, and falls:

- Sustainable, slip-resistant safety flooring: Sustainable, slip-resistant safety flooring is highly recommended in high risk areas.

- Entrance matting: prevents tracking in of moisture, water and wet-dirt.

- Tone contrast: Visual contrast between floors and adjacent surfaces, fixtures, stair edging and furniture is an important design tool. Watch this video for an explanation of ‘Project Rainbow’ by Dr Geoff Cook from the University of Reading in the UK to understand how visual contrast is achieved using light reflective value (LRV).

- Safe stair-design: Stairs are an area of particular concern in any building when trying to reduce slips, trips, and falls. Careful consideration of stair safety is critical in the design phase and South African legislation includes criteria such as uniformity, tread and riser dimensions, type of flooring, stair edgings, tonal contrast and lighting.

Many manufacturers claim that their products are slip resistant/safety floors. What factors/technical aspects can we check to make sure that they are genuine safety floors?

The flooring manufacturer should be able to supply you with technical information to support the following questions.

- Does the product offer sustainable slip-resistance in wet conditions, guaranteed for the life of the floor? Many products are slip-resistant ex-factory but are not guaranteed to be slip-resistant for the life of the floor. It is very important to check this. Quality safety flooring improves its slip-resistance with time.

- Does your product of choice have an official slip rating? Always check this carefully and ensure the necessary tests were conducted in WET conditions. An absolute minimum Pendulum Test Value (PTV) requirement is 36 and new products on the market now rate as high as 50. Learn more about Pendulum Testing.

- Does the product achieve a surface roughness result of 20 microns and above (or higher depending if the floor is installed into a commercial kitchen or food processing areas where oil and grease contaminants may be in evidence)?

Manufacturers and suppliers should be responsible and accurate with the provision of technical data, providing guarantees and assurances where necessary in order for specifiers to meet their obligation.

Uncover the 5 useful questions to ask when selecting a sustainable, slip-resistant floor.

To get insights and expert installation and product selection advice delivered to your inbox, subscribe to Polyflor insights.