Safety is always important and in today's tough economic climate, we are seeing it being sacrificed too often due to lack of budget or knowledge. Denver Coleman discusses the various slip resistance tests and ratings to help you understand the criteria to getting your safety floor specification correct.

“When I look at slip resistance ratings for flooring products, many of them do have a rating. However, it appears there are various tests and ratings. What do these actually mean?” Jaco van der Merwe, Pretoria

How does flooring impact on safety

In countries that typically have a population of 60 to 70 million people, as many as 8 500 accidents caused by “slips and trips” are recorded annually (37% of all total accidents). Apart from costing the economy in excess of R12.5 billion per annum, a further R8.5 billion is lost annually by employers due to lost production. This gives an idea of the value of safety flooring and why specification for the right sustainable product is so important. Therefore, in most countries, legislation requires that public floor areas are installed to comply with fixed safety regulations.

Slip resistance is created by the use of multiple types of aggregates, which create more friction between the shoe sole and the floor. In a good quality, sustainable and slip resistant flooring product, the silicon carbide aggregate granules are not merely sprinkled in the top layer, but appear throughout the thickness of the product. This gives the floors long term sustainable wear and slip resistance. To have a truly slip resistant safety floor, it should test to + 36 RRL on the pendulum test under wet conditions.

Non-slip characteristics are measured in several ways

Safety Standards in flooring

There are several international standards for indicating slip resistance:

Standard EN 13893 DS - dry conditions

The first important test to understand is the EN 13893 DS. This standard refers to slip resistance in dry conditions only and is therefore mostly an irrelevant standard when talking about sustained slip resistance and safety flooring. Standard vinyl flooring will mostly achieve an R9 rating for this standard.

Standard DIN 51130 - laboratory conditions

The next standard commonly used is DIN 51130 on which several products can claim an R10 rating – the scale runs from R9 to R13. This test is carried out under “so called” laboratory conditions. The subject, either shod or barefoot, “walks” on a ramp at an angle until the subject slips. The problem with this test, however, is that it doesn’t take into account wear for measuring slip resistance.

Pendulum RRL Test (recommended) to test slip resistance in flooring

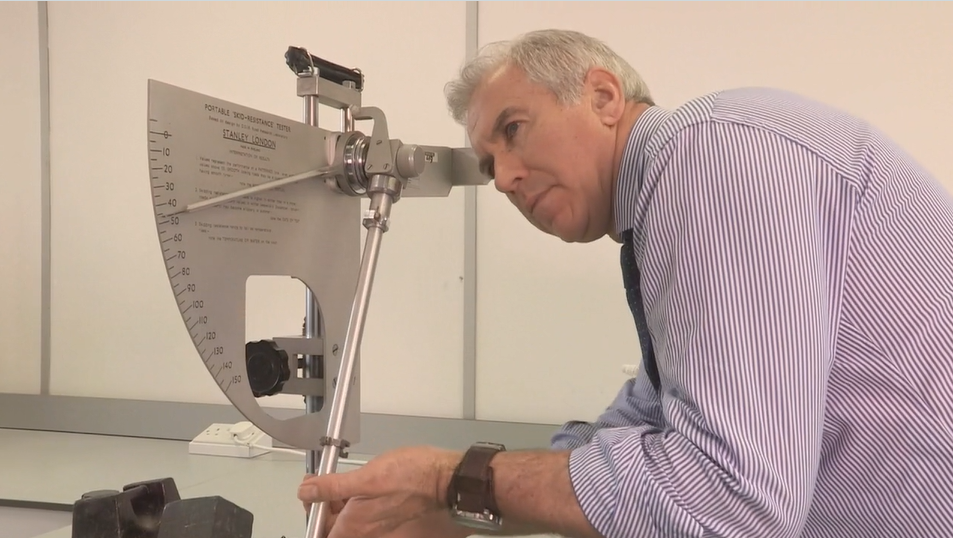

The preferred test is the RRL Pendulum co-efficient of friction test. A + 36 RRL result gives conclusive proof of sustained slip resistance. This test uses the pendulum wet test with a specified 4S (rubber slider 96) to give comparable results under controlled wet conditions. Wet test results indicate a better slip resistance. The pendulum simulates a shoe heel over a wet floor and gives a reading on the pendulum device.

The pendulum machine used for testing slip resistance

The main benefit of the pendulum is, whilst it is used in factory or laboratory conditions, it can also be taken to sites where safety floors are already installed and the slip resistance can be tested on site after some years of use. This is the real test of a safety floor – a good result is “sustainable” slip resistance, even after several years of use in an actual installation and not only in laboratory conditions.

This video shows how slip resistance is tested using the Pendulum Machine.

The Rz Surface Roughness Test

An additional test recommended by the Health and Safety Executive internationally is the Rz surface roughness test and ideally, safety floor sheeting should exceed Rz ≥ 20 µm in surface roughness for specific conditions.

Why is safety flooring important?

By specifying safety flooring in high risk areas a much safer environment is created, protecting people from unnecessary slips and falls. By understanding the various slip resistance ratings one can make an informed choice of the right product for the right application.

Slips, trips, and falls are the highest risk factor for people in any building, regardless of its purpose. Explore how flooring can ensure safety here.

Got a question for Denver? Ask him anything you’d like to know about vinyl flooring!