Sustainability matters at Polyflor. Our vision is to be as carbon neutral as possible, as well as being socially and economically responsible.

As our commitment of ensuring you an environmentally sustainable product, we address the real questions around vinyl flooring.

A cradle to grave analysis:

Are vinyl floors environmentally responsible?

.png?width=312&name=Polyflor%20%20Blog%20Image%20%20Environmentally%20Responsible%20(1).png) Historically vinyl flooring developed an unwarranted reputation as being 'environmentally unfriendly'.

Historically vinyl flooring developed an unwarranted reputation as being 'environmentally unfriendly'.

However, thanks to stringent production methods and globally certified testing of the Polyflor product, this has been proven to be unfounded and untrue.

Local authority Southern African Vinyl Association (SAVA), has again awarded the range their 'environmental thumbs up' Green Tick rating which mirrors the endorsement of organisations around the globe.

Environmental and impact analysis

The most effective and accurate environmental impact analysis of a product is done using a 'cradle to grave' approach and includes an analysis of all stages in the life-cycle of a product. Whilst most vinyl products have good environmental ratings, some are better than others. Polyflor, globally and in SA, are committed to bringing you an environmentally sustainable product.

Polyflor's cradle to grave analysis:

-

Sourcing raw materials

Vinyl is made up of 57% salt (chlorine) and 43% oil (ethylene), salt being one of the world's most abundant resources. All raw materials used in the manufacture of Polyflor vinyl flooring are responsibly sourced from the closest possible suppliers and purchased in bulk to minimise the transport impacts. Suppliers are ISO 14001 certified or demonstrate robust environmental management.

Vinyl is made up of 57% salt (chlorine) and 43% oil (ethylene), salt being one of the world's most abundant resources. All raw materials used in the manufacture of Polyflor vinyl flooring are responsibly sourced from the closest possible suppliers and purchased in bulk to minimise the transport impacts. Suppliers are ISO 14001 certified or demonstrate robust environmental management.

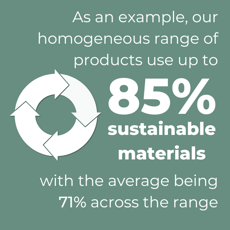

Polyflor floorcoverings predominantly use sustainable materials.

-

The manufacturing process

The manufacturing process for vinyl is the least energy intensive of all flooring products.

Vinyl requires less energy to produce than other plastics, at least 15% less energy than linoleum and 50% less energy than ceramics, due to linoleum and ceramics' lengthy processes in 'ovens'.

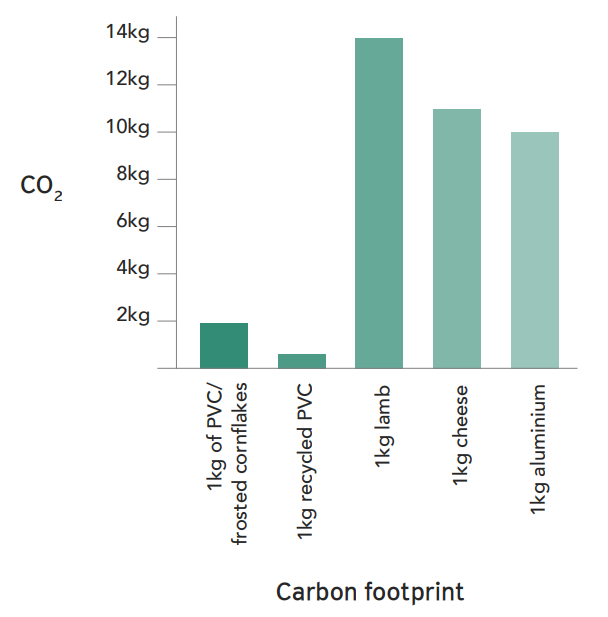

Vinyl is exceptionally energy efficient to produce, and embedded energy is further reduced when recycled material is used in place of raw materials. Vinyl has a relatively low carbon footprint; the same as frosted cornflakes!

Polyflor follows the strictest industry regulations ensuring no harmful substances, such as formaldehyde, lead, cadmium, mercury or hexavalent chromium are included in our vinyl.

-

Packaging

Polyflor flooring is packed in the most effective manner to provide necessary protection, whilst minimising waste. Recycling of various elements in our packaging waste is organised on site, with recycled packaging used where possible.

-

Distribution & transportation

Vinyl flooring is much lighter compared to other flooring materials, allowing reduced fuel consumption in transit.

As a UK manufacturer, Polyflor distributes products from its central distribution centre in the North West of England through a network of wholesalers throughout the UK and around the world, a model that ensures efficiency through the transportation of full, bulk loads.

Polyflor operates its own transport fleet in the UK which is maintained and updated as often as possible to ensure the most fuel-efficient vehicles are used. Further reductions of the fleet's environmental impact are achieved by improving driving efficiencies, using the shortest routes possible and increasing bulk loading and backhauling volumes.

Polyflor operates its own transport fleet in the UK which is maintained and updated as often as possible to ensure the most fuel-efficient vehicles are used. Further reductions of the fleet's environmental impact are achieved by improving driving efficiencies, using the shortest routes possible and increasing bulk loading and backhauling volumes.

Polflor SA ensures sustainable transport of goods wherever possible.

-

Installation

Polyflor continues to develop and improve installation methods for its flooring ranges, with increased use of solvent-free adhesives and adhesive-free vinyl flooring, such as Expona SimpLay, Secura, Designatex and Architex. The added benefit of adhesive free flooring is the ability to recycle and reuse the product

-

Maintenance

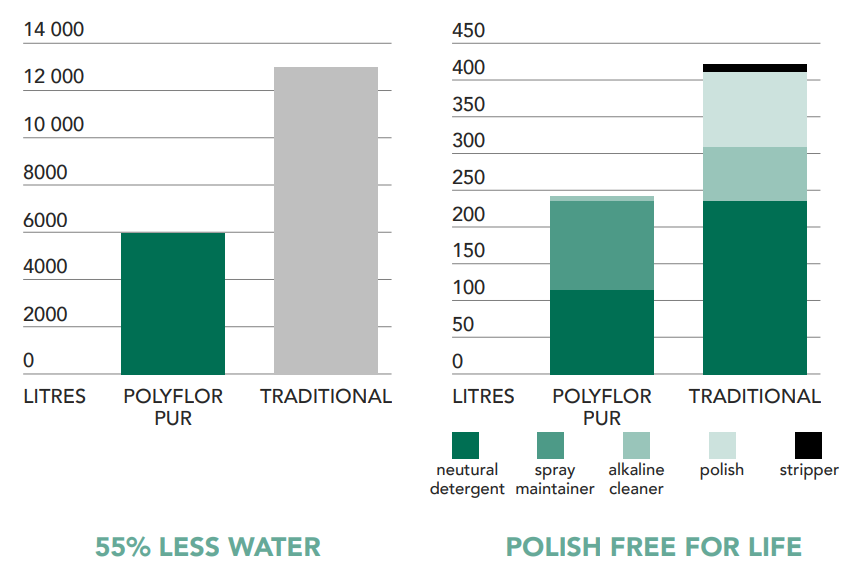

The 'in-use' phase of any flooring accounts for 80% of its environmental impact. Factors such as the sustainability, cost and efficiency of cleaning methods and cleaning products need to be considered.

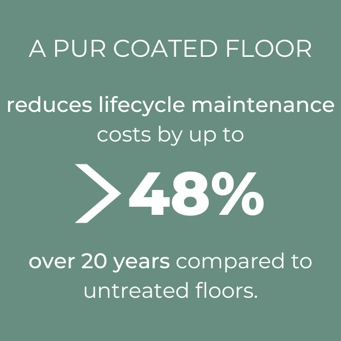

Most Polyflor products are designed with low-maintenance features including a Polyurethane (PUR) reinforcement coating which ensures superior cleaning benefits, enhanced protection and optimum appearance retention. The PUR coating is environmentally sustainable ensuring less use of energy, polish, water and cleaning chemicals.

-

Durability

Vinyl offers excellent durability. The longer a product lasts, the less energy and other resources are needed to produce, deliver and install a replacement. The official life-cycle of vinyl is 20 - 25 years but with a good maintenance regime, it can literally last a lifetime. Vinyl is also naturally fire resistant.

-

Disposal of the product

Polyflor South Africa is piloting a 'first-of-its-kind' recycling initiative for recycling and disposing of vinyl (there is always waste on site and it's expensive to dispose of). This innovation has evolved from the initial programme started in 2017.

-

Air quality

An important part of environmentally sustainable floors is their VOC emissions, which affect the air quality in a building.

Some interesting facts about Polyflor's impact on the quality of air:

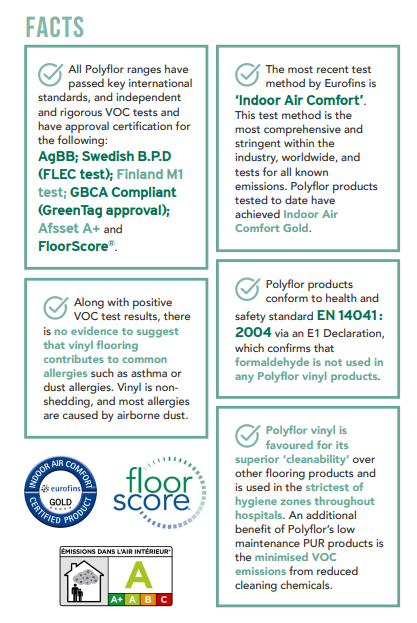

- All Polyflor ranges have passed key international standards, and independent and rigorous VOC test and have approval certification for:

- AgBB

- Swedish B.P.D (FLEC test)

- Finland M1 test

- GBCA Compliant (GreenTag Approval)

- Afsset A+

- FloorScore

- The most recent test method by Eurofins is 'Indoor Air Comfort'. This test method is the most comprehensive and stringent within the industry, worldwide, and tests for all known emissions. Polyflor products tested to date have achieved Indoor Air Comfort Gold.

- Polyflor products conform to health and safety standard EN 14041:2004 via an E1 Declaration, which confirms that formaldehyde is not used in any Polyflor vinyl products.

- Along with positive VOC test results, there is no evidence to suggest that vinyl flooring contributes to common allergies such as asthma or dust allergies. Vinyl is non-shedding, and most allergies are caused by airborne dust.

- Polyflor vinyl is favoured for its superior 'cleanability' over other flooring products and is used in the strictest of hygiene zones throughout hospitals. An additional benefit of Polyflor's low maintenance is the minimised VOC emissions from reduced cleaning chemicals.

For more detailed information on the sustainability of Polyflor's products please download the latest Polyflor Sustainability Report.

Read more about our commitment to sustainable flooring products and solutions.

Download our latest eBook and discover how the triple bottom line applies to vinyl flooring.